• Use industrial computer to control.

• Support multiple languages, and can input in Chinese, English or handwriting.

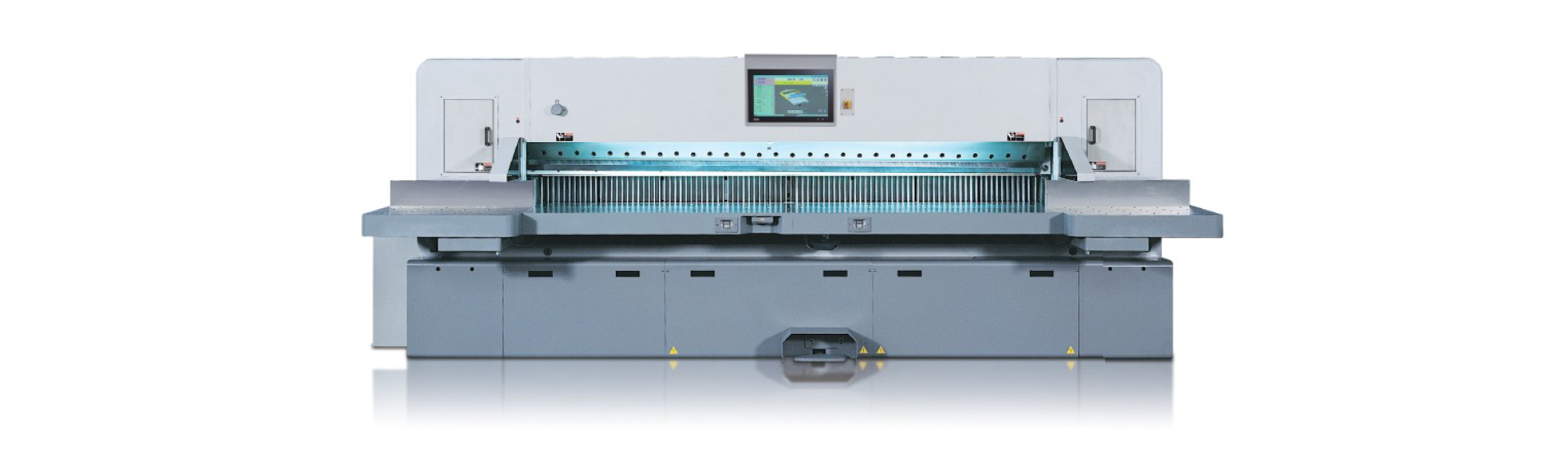

• Gtaphical operation interface.

• Automatic notification for periodic maintenance.

• With computer function and optional functions such as isometric, cutting label, cutting memory, paper pushing and air supply, etc.

• Cutsomer name and bill name can be entered in Chinese or English or handwritten and quick query.

• 1000 groups of customer names, a total of 100,000 programs can be set.

• AC servo control system, locating accuracy of the back-gauge +/- 0.01, total tolerance 0.02mm.